While battery electric vehicles (BEVs) are powered by large lithium-ion (Li-ion) battery packs, consumers will be surprised to know that the conventional 12 V lead-acid battery also continues to be part of a BEV’s battery system. Although, lately some EV makers like Tesla have replaced lead-acid with Li-ion. Nevertheless, like internal combustion engines (ICE), it continues to power many of the same functions required in cars, such as lights, wipers, radio/sound, dashboard instruments, doors, navigation system, on-board computer and so on. According to Vicor, with the absence of a harmonized, scalable approach for delivering electric power, the car manufacturers are grappling with a major design hurdle. How to handle vehicle’s subsystems that 12 V battery has long supported.

“This is compounded by a tremendous increase in power requirements,” says Patrick Kowalyk, Vicor’s principal field applications engineer for automotive. According to Kowalyk, BEVs need power levels up to 20 times greater than cars with ICE engines. “That 20x surge means a corresponding increase in power electronics that adds cost, weight, size and design complexity,” added Kowalyk.

As a result, today’s sub-optimal solution is to pack BEVs with as many as three separate batteries. In addition to a 400 V or 800 V battery pack, (traction battery), there is a distribution system that operates from secondary 12 V and 48 V batteries.

Vicor’s answer to this design dilemma lies in enabling the traction battery to serve in the same capacity as the 12 V battery by replacing it with a solid-state power delivery network that improves vehicle performance while saving space and weight.

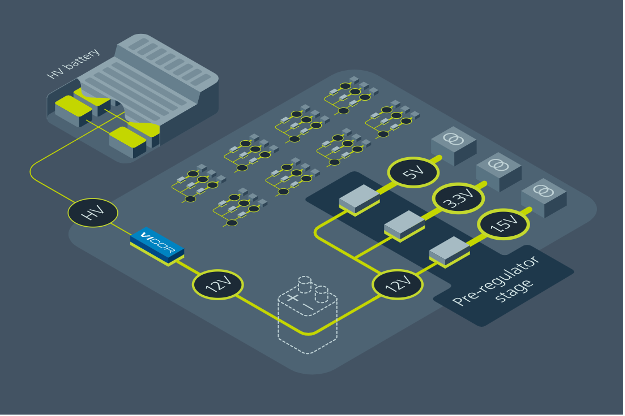

Consequently, the power supply manufacturer is working with automotive suppliers and OEMs to eliminate these supplemental power sources by creating a ‘virtual battery’ that responds three times faster than standard 12 V battery,” asserted Kowalyk. “The solution is a high-performance, modular power converter that converts power from the main 400 V or 800 V high-voltage battery down to 12 V or 48 V levels with such a fast response time that a separate battery is no longer needed (Figure 1).” In essence, noted Kowalyk, “by switching to modular power you can eliminate the 12 V battery and achieve enhanced transient response, decreased weight and additional package space, all contributing to extended range and better overall vehicle performance.”

Vicor study shows that this replacement strategy not only allows engineers to replicate the essential properties of a physical 12 V battery, it enables them to remove more than 25 pounds of vehicle weight and creates enough saved space to fit the equivalent of a small, carry-on suitcase. In 2022, the company expects to see this modular approach to power delivery being adopted by OEMs that are looking to electrify and differentiate their fleets with extended range and better overall performance.